| Produktpreis | 100,00 $ |

| Liefern von | Dongguan, Guangdong Province, China |

| Lieferfähigkeit | 100000 pieces / week |

| Durchschnittliche Produktionszeit | 3 days |

| Product packaging | plastic box |

| Shipping packaging | carton box |

| Incoterms | EXW |

| According to customers' design(size,material,thickness,process content and required technology ,etc. All goods will provide inspection report when completed Ensure customers drawing privacy,protect the customer's market Samples are accepted OEM and ODM are welcome | |

| Tolerance | +/-0.01-0.01 |

| Roughness | Ra0.8(customize available) |

| Material Available | Aluminum,copper,Stainless Steel,PE,PVC,ABS etc. |

| Surface Treatment | Polishing, Surface chamfering, general/hard/color oxidation |

| Process | CNC Turning,Milling Parts,Drilling , Auto Lathe,Tapping,Bushing,Surface Treatment,etc. |

| Test Equipment | CMM/Tool Microscope/Height Gauge/Roughness Measurement |

| Business scope | Metal parts processing ,assembly, fixtures design and manufacturing |

FAQ

Q: Are you trading company or manufacturer?

A: We are a manufacturer

Q: What do you need to provide a quote?

A: Please kindly send us the drawing of your product. Details below should be included,

1.Materials 2. Tolerance 3.Surface Finish 4.Quanitity

Q: How long is your delivery time?

A: Generally it is 7-15 days for samples and 30-45 days for mass production, it depends on quantity.

Q: Do you provide samples?

A: Yes, we could offer the samples.

Company Informaton

Our factory focused on professional production of technical, provides the service of designing and Manufacturing for CNC machining precision parts, Medical Instrument spare parts, Communications Equipment (Resonator, Filter, RF Cavity and etc), Machinery spare parts, Precision fastener and etc.

We own several advanced equipments such as JapanBrother vertical 5-axis machining center, Makino CNC, JR Automatic and Hexagon CMM, plus the application of the advanced Software like Mastercam, UG, Creo to aid the analysis, design and processing.

We have established a comprehensive processing and quality control system. It provides the Design and manufacture for precision processing. There is a high quality team in Bijian who always Draw on the advanced experience of the fellow both at home and abroad, zealously with an open Learning attitude to try their best to provide high precision and high quality product for their customers.

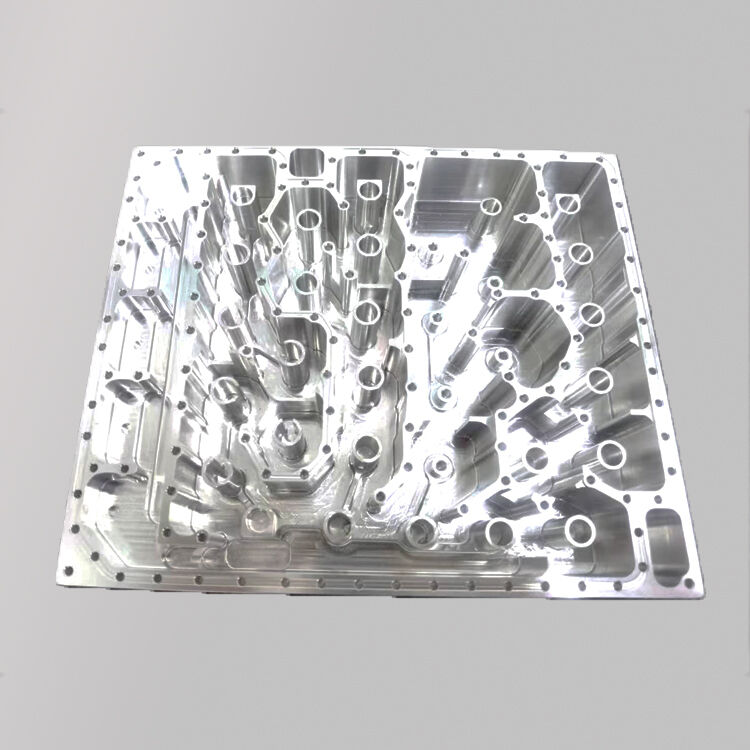

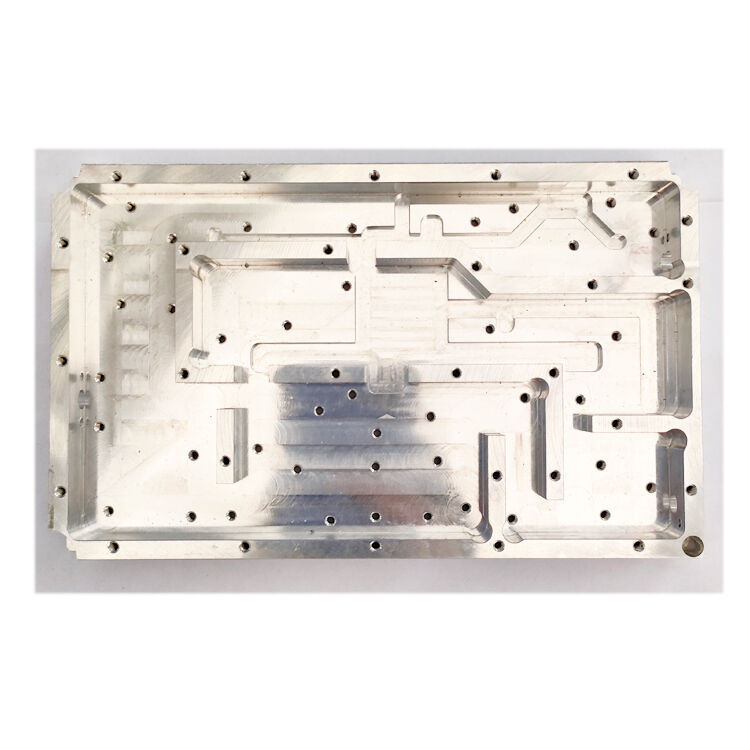

Customized CNC Precision Aluminum Machining Part

123bijian CNC machining

Customized CNC Precision Aluminum Machining Part

123bijian CNC machining