Silicone rubber was first introduced as an insulation material for electrical equipment. It is an elastomer manufactured through curing or molding, notable for its versatility and ease of manufacturing and forming. Along with good temperature and environmental resistance, silicone rubber made its way into many industries.

Bestellung in Silicone Rubber

| Property | Value |

|---|---|

| Tensile strength | 5.5 N/mm2 * |

| Elongation at break | 360% * |

| Tear strength | 25 N/mm * |

* Number for Shore 40 A rubber for vacuum casting

Before curing and forming, silicone rubber appears as a liquid gel with good adhesive properties. In its liquid state, it is used for life-science applications and optical products as well as some cosmetics. In cured form, it appears as synthetic rubber. One of the most common types of silicone rubbers is polydimethylsiloxane or shortly PDMS.

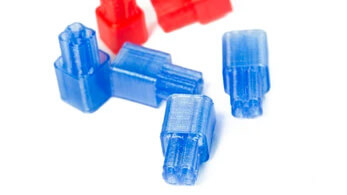

Commonly, after liquid rubber is mixed with all necessary additives and colored, it can be extruded. Silicone rubber comes as tubes, strips, or custom shapes. It is mainly utilized for applications that require retention of the original shape along with mechanical strength.

Advanced performance in low temperatures and characteristics such as biocompatibility also open doors to silicone rubber in medicine, food preparation, and automotive spheres.

Silicone rubber can be manufactured in different shore hardness, which influences the flexibility of a material. It is also available in nearly every possible color. Additionally, it can have enhanced properties through additives, thus, steam resistant, metal detectable, high tear strength, extreme temperatures resistant, electrically conductive, low smoke emitting, and flame-retardant options are available.

CNC machining of silicone rubber is complicated, especially on less hard grades. However, it is possible to grind, drill and cut rubber sheets and shapes on CNC cutters.

Laser cutting and engraving of silicone rubbers are able to deliver smooth and clean cuts with precision and high details. The only possible downside to look for is slight burnings on the edges.

Silicone rubbers are easy to form through casting and injection molding. This material is described to provide stable quality from batch to batch, thus, suitable for high-volume production. Along with short cycle time and no waste during molding, it is a fine medium to work with.

Silicone rubber in low shore hardness is potentially the most flexible material for O-rings. Focus on rubber with low filler content for extra flexibility as well. However, it is critical to consider the conditions and application of the O-rings since silicone rubber may not be the best choice for dynamic parts.

Without special fillers, silicone rubber is not electrically conductive.

Alle Kommentare (0)