| Produktpreis | 10.000,00 $ |

| Liefern von | Qingdao, Shandong, China |

| Lieferfähigkeit | 30 sets / day |

| Durchschnittliche Produktionszeit | 30 days |

| Product packaging | Chipboard packaging |

| Shipping packaging | Crate |

| Incoterms | FOB |

FEATURES

High strength machine bed

High-strength machine tool, adopting 600℃ high temperature annealing treatment, with integrated machine rigidity;

The overall mechanical structure has small deformation and low vibration, ensuring cutting accuracy.

5 axis cnc machining center drilled all holes for linear rail and helical gear,which keeps high accuracy.

Cast iron gantry support

It comes standard with gantry support which is made of cast iron. Compared with welding iron gantry support,this model has much more stability.

Adjusting screw fixed between gantry and gantry support---when we install machine ,we will adjust vertical accuracy of x and y axis less than 0.03mm,and install this screw, first this screw can keep vertical accuracy,second,this screw can be used for adjusting if the accuracy changes after many year later.

It comes standard with 30mm linear rail and M2 helical gear.

Automatic sorting and processing of NC files in Taiwan syntec 60CA controller ---In this controller this is one operation menu as the following picture shows,all files will be sorted by numbers or initial letters, then machine will run those files one by one.So operators can change material and press start button on the back of machine, no need to go to control cabinet and operate.

Inovance 850W servo motor and driver for x y z axis

Inovance servo motors offer compact design, quiet running modes and high performance.

Connect to M2 helical rack and Japan shimpo reducer,this kind of servo keeps fast working speed and higher accuracy. Max travelling speed is 60m/min.

New designed dust free dust collector hood, which ensures that nearly no dust left during cutting.Please check machine working video,we add air blast in dust collector hood,which will help dust going into dust collector pipe during machining.

Double layer nesting vacuum table with 160 vacuum holes---there is gap between those two layer vacuum table, so this kind of table will hold material much more flat and more tightly.

12-position linear tool magazine installed under gantry

This kind of tool magazine reduces time for change tool,which increase working efficiency of this machine

China brand CC 9.0KW spindle---1. Using P4 grade centripetal anti-thrust ball bearing (or ceramic bearing) greatly improve the strength and rigidity of electro-spindle, and its speed can up to 24000 RPM/min.

2.All moving parts need to pass the high precision test of dynamic balancing to ensure the residual value is lower than G0.4 degrees.

3. The IP grade of electro-spindle can reach IP54 by protection of aluminum made airtight pedestal, and protect the internal components from the threat of dust.

4.Equipped with independent electric fan as cooling device, even when electro-spindle stop working, this scheme can bring a moderate amount of air for cooling and maintain very low noise.

Button boxed installed on the back of the table---this button box includes Start button, Reset button,Emergency stop button and also cylinder button,which is installed on back of table.so after finish cutting, operator can change new material and then press start button directly, machine will run next program continually.

Protect cover for the spindle

Automatic unloading pusher design

Unloading pusher will unload panels to unloading tables after finish cutting

Auto sensor for measuring tools automatically---machine will measure those tools with high accuracy through this tool sensor

| Series | NA-49P |

| Working size | 1220*2800*150mm |

| Table size | 1220*2800mm |

| Transmission | X Y rack and pinion,Z ball screw |

| Spindle | 9kw ISO30 |

| Travelling speed | 50m/min |

| Working speed | 20m/min |

| Driving system | Inovance |

| Controller | Syntec |

| Voltage | AC380V/220V,50/60HZ,3PH |

| Dimension | 4100*2260*2150mm |

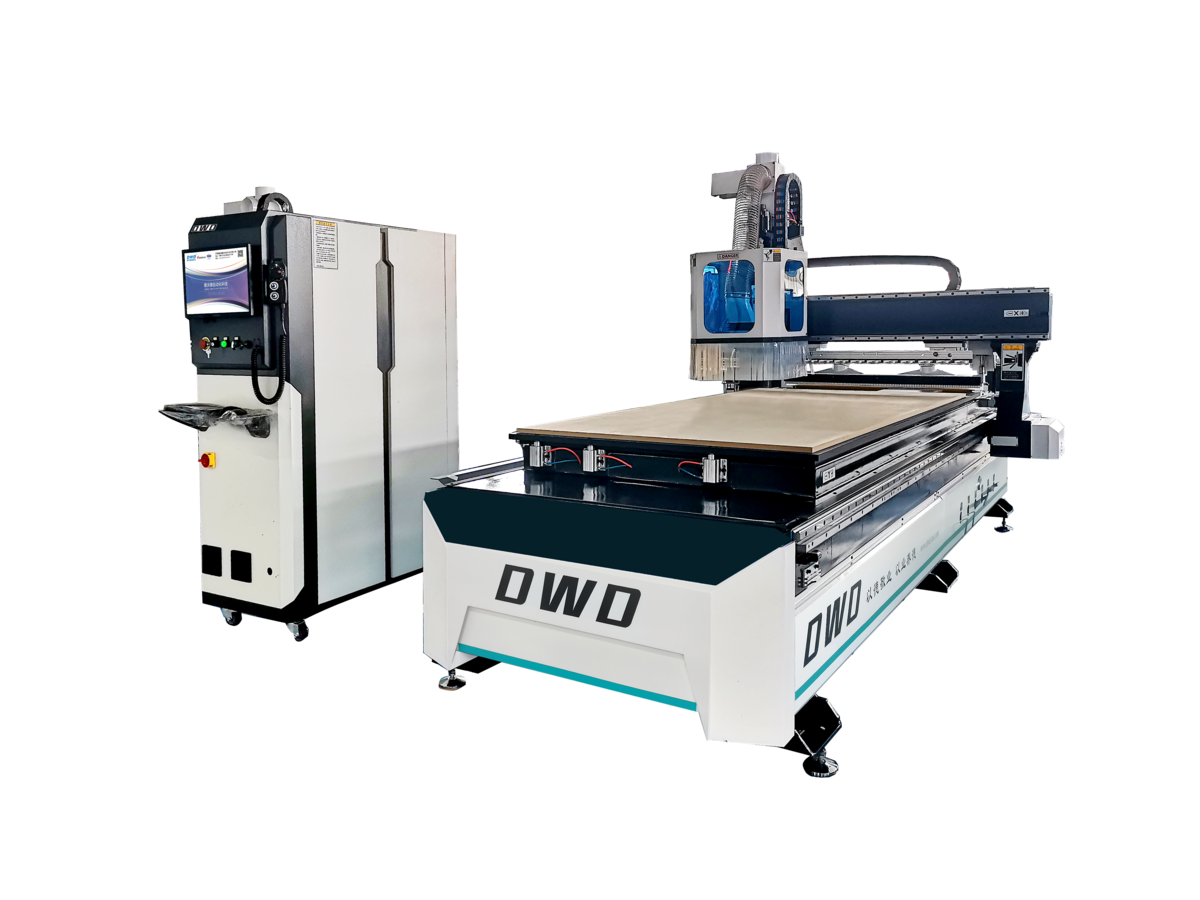

DWD Auto Flip cnc nesting machine

123DWD CNC nesting machine center NA-2821F

DWD Auto Flip cnc nesting machine

123DWD CNC nesting machine center NA-2821F  DWD Auto Flip cnc nesting machine

123DWD CNC nesting machine center NA-2821F

DWD Auto Flip cnc nesting machine

123DWD CNC nesting machine center NA-2821F  DWD Auto Flip cnc nesting machine

123DWD CNC nesting machine center NA-2821F

DWD Auto Flip cnc nesting machine

123DWD CNC nesting machine center NA-2821F  DWD Auto Flip cnc nesting machine

123DWD CNC nesting machine center NA-2821F

DWD Auto Flip cnc nesting machine

123DWD CNC nesting machine center NA-2821F  DWD Auto Flip cnc nesting machine

123DWD CNC nesting machine center NA-2821F

DWD Auto Flip cnc nesting machine

123DWD CNC nesting machine center NA-2821F